A successful process hazard analysis (PHA) program proactively identifies and mitigates risks while ensuring full alignment with client and regulatory requirements. We implement a safety-first approach for all phase projects which promotes early mitigation and minimal process adjustments when scaling. The magnitude of the safety risk increases with the size of the batch and must be identified early for efficient scale-up or transfer. Laboratory scale reactions are undertaken with controlled risks that may require more complex engineering controls when scaling to commercial reactor sizes, e.g., cooling requirements for exothermic reactions. Our breadth of tools and expertise helps identify risks efficiently and accelerate time-to-market for development and transfer projects.

Integrated Hazard Lab Solutions

Veranova’s hazard lab provides comprehensive testing and safety assessment services to support every phase of pharmaceutical development, from early development through to commercial manufacturing. The process safety team involves a multidisciplinary collaboration between chemical research and development (R&D), analytical R&D, and engineering experts to deliver a seamless, end-to-end safety management solution. Hazardous chemistries are identified early through a combination of digital modeling tools and targeted experimental screening. This integrated approach informs process design, optimizes reaction conditions, and enables effective risk mitigation from the outset.

Process Safety Capabilities

- Digital Screening Tools: AKTS Thermokinetics Software (Advanced Kinetics and Technology Solutions SA), CHETAH (Chemical Engineering Thermodynamic and Hazard Analysis, ASTM International), Dynochem (Mettler Toledo), additional mixing and heat transfer simulation tools, and in-house, proprietary tools allow us to model and predict process risks, optimize reaction conditions, and help to ensure right first-time scale-up.

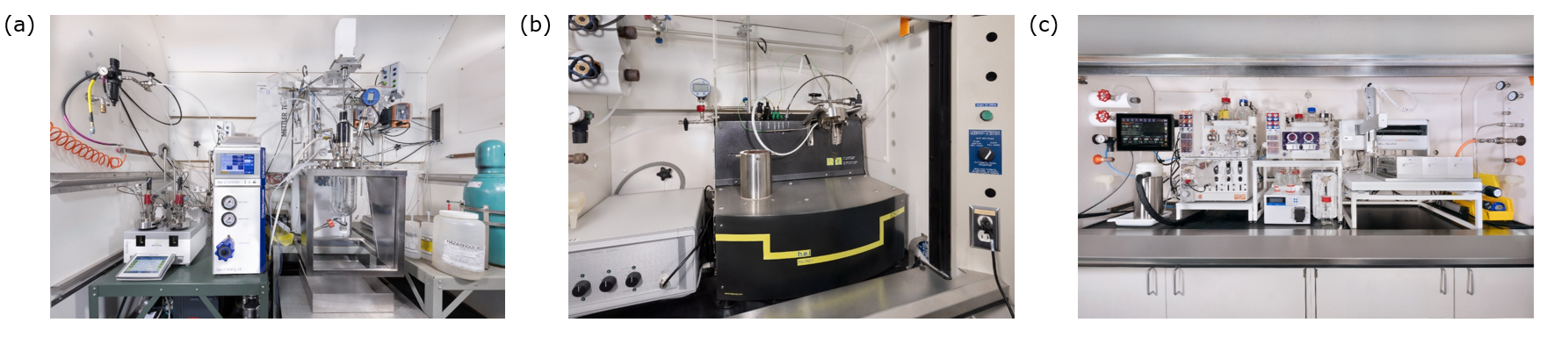

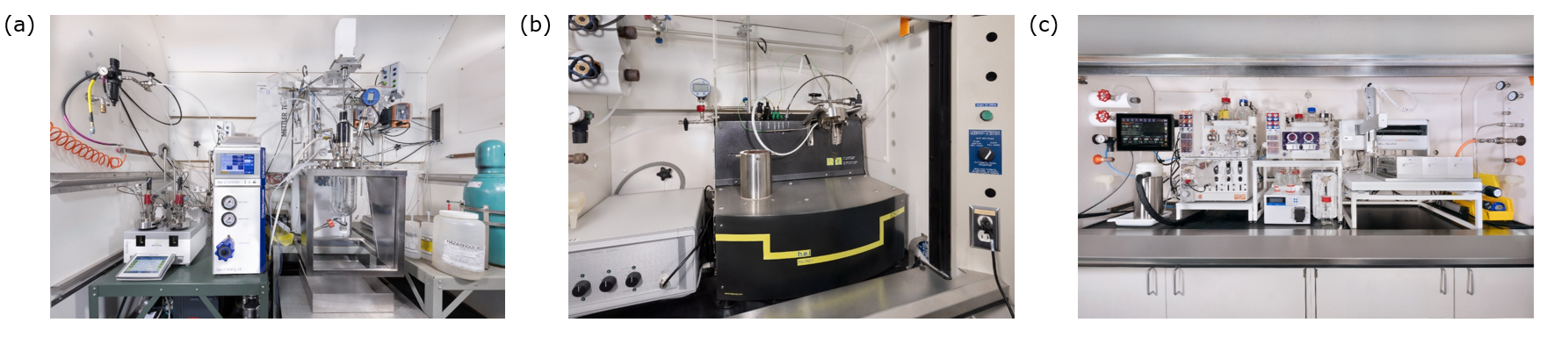

- Thermal Hazard Assessment: Calorimetry tools include Mettler Toledo DSC 3+, RC1e, EasyMax HFCal, and HEL Phi-TEC I (Figure 1a,b). Thermal and adiabatic calorimetry is performed to identify exothermic events, measure heat release, and assess thermal runaway potential.

- Flow Chemistry & High-Throughput Analytics: Platforms such as Vapourtec R-Series and iChemExplorer (Figure 1c) enable safe handling of hazardous intermediates and rapid optimization of synthetic routes, ensuring scalability and safety for challenging chemistries.

Figure 1: Selected automated chemistry and calorimetry instruments (a) Mettler-Toledo RC1e and EasyMax 102 with Büchi pressure controller—enables pressure regulation and calorimetric studies (b) HEL Phi-TEC I adiabatic calorimeter—designed for advanced thermal hazard analysis, enables true adiabatic calorimetry for quantifying runaway potential (c) Vapourtec R-Series flow chemistry system for reduced operator exposure and high throughput screening.

Structured Process Hazard Analysis Framework.

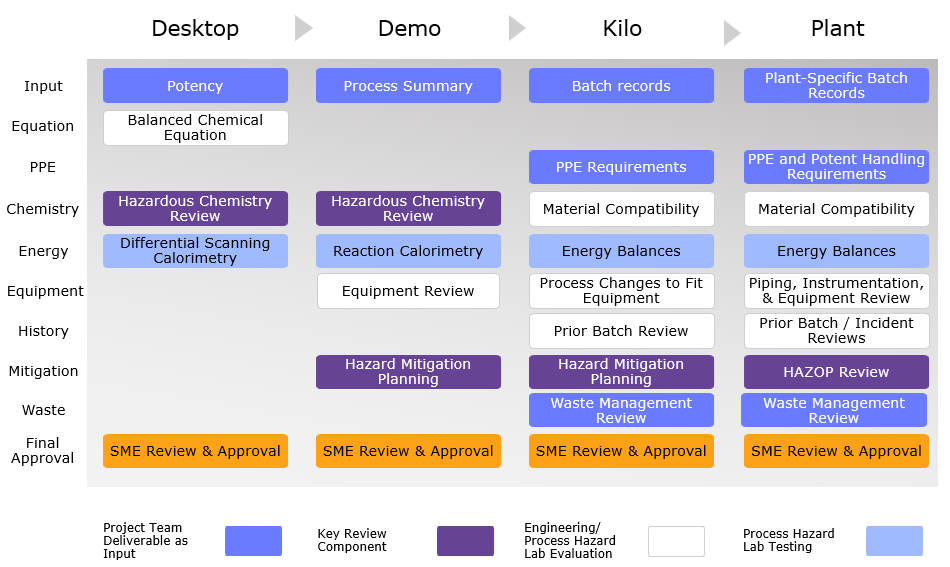

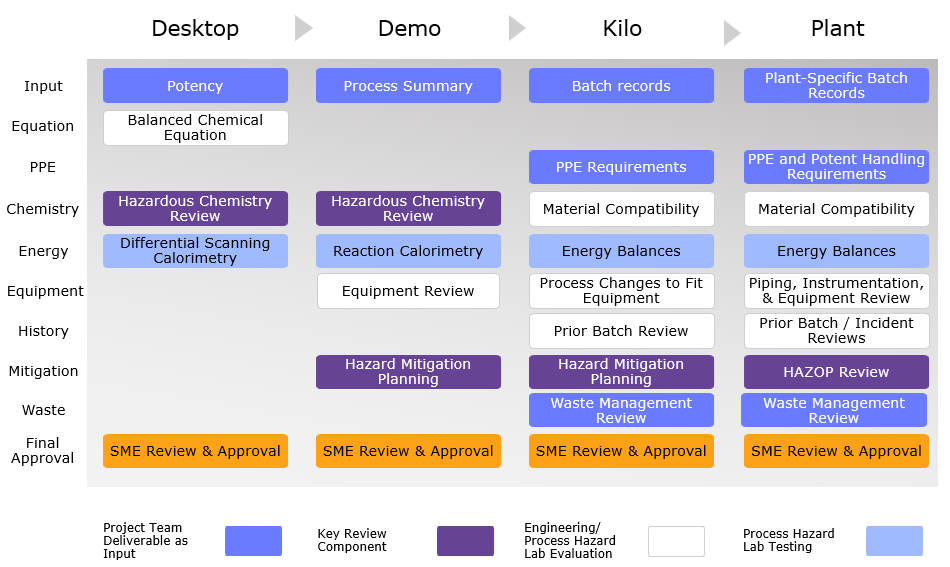

Our tiered process hazard analysis (PHA) framework (Figure 2) defines a structured methodology for the evaluation and management of risk throughout development and scale-up. This approach champions industry standards (e.g., Ayman et al.1) to affirm every process step is thoroughly reviewed and mitigation strategies are implemented as projects advance from laboratory to manufacturing. At each stage, a cross-functional team of subject matter experts (SMEs) reviews findings, agrees on action plans, and documents steps to promote the highest safety and compliance standards. As needed, additional strategic partnerships with leading hazard and process safety consultants supplement our internal team. These collaborations provide access to advanced modeling, emergency relief system design, and incident investigation resources to further enhance our PHA.

Figure 2: Tier-based PHA workflow scaling from desktop to plant—parameters for stage appropriate evaluation. Process and hazard review is additive as the project progresses across scales.