Over the last 40 years, the application of cannabis-derived medicines in the pharmaceutical sector has come a long way. Around the world, there has been a huge increase in patient interest for using cannabinoids to treat a variety of conditions, including depression, cancer, pain and neurological disorders. At the same time, within the pharmaceutical sector, there has been a wider acceptance of the product as a treatment and as a result, an increased rate of research into the application of the cannabinoid family.

Ultra-pure synthetic cannabidiol (CBD)

We’re utilising our scientific and manufacturing expertise to develop and commercialize ultra-pure synthetic cannabinoids that meet the quality requirements demanded by the pharmaceutical industry.

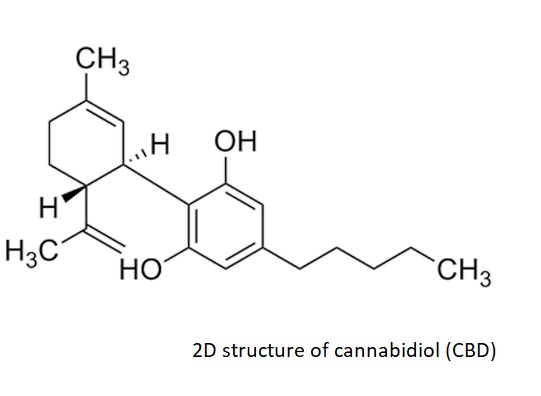

Cannabinoids are naturally occurring compounds found in the Cannabis sativa plant. There are over 200 known cannabinoids, however, the most recognised are tetrahydrocannabinol (THC) and cannabidiol (CBD). THC was the first cannabinoid to be studied extensively for its therapeutic potential. And as such, the first cannabinoid-based product to be approved by the FDA was the synthetic THC analogue, Marinol, in 1985. More recently, at a scientific level, attention has tended to shift away from use of THC, due to its psychoactive intoxicant effects, towards CBD and its potential therapeutic applications.

Synthetic routes

In addition to the increasing interest, research into medicinal cannabis is also becoming easier. Countries around the world are beginning to relax regulations for cannabis use in medical situations, leading to fewer restrictions for researchers looking to investigate its potential applications. Conversely, for pharmaceutical developers the lack of standardised protocols makes cannabinoid-based drug development challenging to manage as many countries have their own specific rules on the import and export of certain cannabinoids. While there have been improvements to the standardisation of regulations, country-to-country harmonisation is still far from a reality. This is particularly seen in the United States, where a disconnect between federal and state regulations is causing operational challenges for many operating in the sector and made it ever-more challenging to achieve regulatory approval.

For a potential cannabinoid active pharmaceutical ingredient (API) to navigate the complex and often confusing regulatory minefield, manufacturers must understand and meet strict quality controls on purity and consistency. For instance, drugs using CBD as the API must ensure they meet extremely low THC thresholds and avoid the psychoactive side-effects. This becomes vital in applications such as paediatrics, where healthcare professionals must be assured that these side effects will not occur.

To ensure regulations are kept to, and to safeguard the health of potential cannabis product consumers, the industry is increasingly looking to apply optimised, synthetic routes to manufacture cannabinoids. Compared to cannabinoid extraction from plant products, these methods provide a greater level of control over every available parameter, helping to improve the yields of products while avoiding any impurities and contamination.

Deep roots

With the growing requirement for Good Manufacturing Practice (GMP) grade material within the pharmaceutical sector, drug developers are increasingly seeking out experienced partners in the development and manufacture of cannabinoids. Our involvement with pharmaceutical cannabinoids started 15 years ago when helping a customer develop a generic substitute for Marinol. Working with cannabinoids is very complex as the APIs produced can be challenging to work with. For example, in Marinol, the API oxidizes quickly and is prone to impurities. To support the launch of the generic, Veranova invested tens of millions of dollars in large-scale supercritical fluid chromatography and other equipment at its West Deptford, N.J., plant, to achieve the high purity needed to prevent THC from oxidising readily.

Through the cannabinoid expertise generated through this generic substitute, we were able to develop a novel synthetic method for producing ultra-pure free-flowing CBD powder. To gain FDA approval, you need to produce a very pure product, which requires the right equipment and a significant amount of technical know-how. As well as developing a validated process for cannabidiol synthesis (filed with a US DMF), we have also created reference standards for our cannabinoids, which help our customers understand what they are getting, and gives them the confidence to use our APIs in their formulations.

Beyond THC and CBD, there are well over one hundred different cannabinoids within the cannabis plant, and pharma companies are interested in assessing the therapeutic potential of a number of these. In response, we are planning to expand our portfolio to include other synthetic cannabinoids.

Future of synthetic cannabinoids

The future for cannabis-based therapeutics is very bright. And with new players in the field, it is vital to ensure that partnerships with established forces are forged. At Veranova, we believe that strong particle engineering and manufacturing solutions will play a crucial role in further developing the industry. With the right scientific expertise and manufacturing capabilities, we can ensure the development of therapeutics that will help forge a better, innovative tomorrow.