The Essence of ADCs

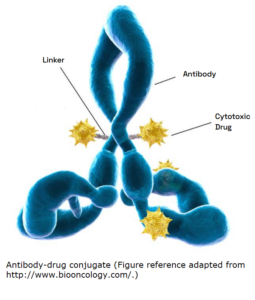

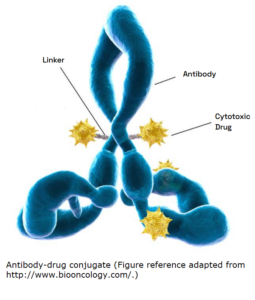

ADCs are a harmonious blend of immunotherapy and chemotherapy, presenting formidable weapons against a spectrum of tumor types. Characterized by their ability to target over 50 distinct recognized antigens, ADCs predominantly focus on ERBB2, CD33, CD19, CD22, and MSLN (mesothelin). The idea is captivating yet intricate: direct a cytotoxic drug to its tumor target using an antibody linked through a carefully designed linker.

ADCs are a harmonious blend of immunotherapy and chemotherapy, presenting formidable weapons against a spectrum of tumor types. Characterized by their ability to target over 50 distinct recognized antigens, ADCs predominantly focus on ERBB2, CD33, CD19, CD22, and MSLN (mesothelin). The idea is captivating yet intricate: direct a cytotoxic drug to its tumor target using an antibody linked through a carefully designed linker.

Despite the initial enthusiasm heralded by Pfizer’s Mylotarg in 2000, the ADC realm witnessed a series of ups and downs. Challenges in designing an effective ADC and concerns over toxicity meant the journey was far from smooth. However, the recent surge in interest can be attributed to refining conjugation technologies, which have created more stable and precise ADCs.

Despite only a few ADCs obtaining FDA approval, many novel therapeutics are progressing through clinical pipelines. Innovations in the field are diversifying production techniques, underscoring the importance of understanding, scaling, and optimizing manufacturing methods to meet clinical and commercial needs. With potential pitfalls and regulatory hurdles looming, affiliations with proficient CMOs grounded in strong linker payload synthesis capabilities become invaluable.

Development and Manufacturing of ADC’s

The Importance of Phase-Appropriate Processes:

Implementing phase-specific processes, especially for early-phase clinical supply, is essential to fully harness the FDA’s strategies to facilitate ADCs’ market entry. Expert CMOs can adeptly transition laboratory processes to GMP suites. Initial explorations at small scales (1-10 mL) to identify process sensitivities can be expanded upon with subsequent process development at 10-100mL and further validation at 0.1-10L scales. Employing a simulation-based approach at each developmental phase, complemented by corresponding analytical methods, smoothens progression to Phase 2 clinical trials.

Given the possibility of Phase 2 trials becoming pivotal for ADCs, ensuring the commercial readiness of the Phase 2 manufacturing process is crucial. Employing a layered process characterization strategy can be an efficient method to streamline program timelines. Forward-thinking CMOs often intertwine certain PPQ activities to mitigate potential delays.

Advantages of Early Process Characterization

Bringing forward process characterization to the initial stages, like phase I can enable earlier performance qualification. While potentially compressing timelines, this strategy requires extensive manufacturing experience and a solid platform process to minimize risks.

Process characterization, pivotal for a drug’s lifecycle, can be a formidable task for many organizations, necessitating collaborations with CMOs for swift market progression. A seasoned CMO, backed by multiple process characterization ventures, can provide a resilient framework for market approval. From planning to sophisticated biopharmaceutical testing, the comprehensive capabilities render CMOs invaluable partners in ADC development.

The Role of CDMOs in ADC Manufacturing

A partnership with seasoned CDMOs can streamline ADC manufacturing processes. With their profound understanding of scientific, technical, and regulatory aspects, these organizations can offer indispensable support throughout the ADC manufacturing lifecycle. The urgency to bring therapeutics to patients and achieve commercial success emphasizes minimizing time-to-market. A systematic approach involving process/analytical development, appropriate site selection for manufacturing, and performance qualification at the manufacturing scale can curtail the chances of unwanted late-stage alterations.

A partnership with seasoned CDMOs can streamline ADC manufacturing processes. With their profound understanding of scientific, technical, and regulatory aspects, these organizations can offer indispensable support throughout the ADC manufacturing lifecycle. The urgency to bring therapeutics to patients and achieve commercial success emphasizes minimizing time-to-market. A systematic approach involving process/analytical development, appropriate site selection for manufacturing, and performance qualification at the manufacturing scale can curtail the chances of unwanted late-stage alterations.

Analytical Techniques for ADC Characterization

The inherent complexity of ADCs necessitates sophisticated analytical methods for their thorough characterization, such as high-resolution mass spectrometry, ion mobility-mass spectrometry, and various chromatographic techniques. Characterizing these biologically engineered drugs goes beyond determining their DAR. Analytical methodologies are pivotal in assessing purity, drug linkage, free drug detection, and long-term stability. These methods ensure that the ADCs are potent and safe for patient administration. Analytical challenges include preserving noncovalent interactions in the ADC structure and accurately quantifying payload stoichiometry. Introducing ion mobility-mass spectrometry adds an extra dimension to ADC analysis, offering insights into their molecular shape and form. Alternate techniques like UV/Vis spectroscopy and hydrophobic interaction chromatography are also explored for their potential in determining DAR values. Given the possible aggregation risks in ADCs, it’s crucial to employ comprehensive methodologies like SEC, AUC, and FFF for accurate characterization. In summary, the analytical rigor required for ADCs underscores their complexity and the necessity for advanced techniques in their development and evaluation.

Challenges in ADC Production

Despite the burgeoning promise of Antibody-Drug Conjugates (ADCs) in therapeutic settings, their manufacture is mired in a series of formidable challenges. A convoluted supply chain often necessitates the involvement of multiple production facilities, ensuring that each step adheres to the intricate requisites of the production process. This complexity is further compounded by the stringent safety protocols essential for workers and the final product’s end users. Moreover, the inherent variability in ADC products underscores the need for advanced analytical capabilities, ensuring consistent efficacy and safety in each batch produced. Forging a robust collaboration with a proficient Contract Development and Manufacturing Organization (CDMO) can be instrumental in considering these challenges. Notably, the essence of ADCs, akin to other biologics, is inextricably linked to their production processes. In this context, partnering with a Contract Manufacturing Organization (CMO) with profound technical expertise can usher in a transformative change in ADC development. The invaluable insights such CMOs provide, especially in rapid scale-up, bespoke method development, and comprehensive process characterization, can prove pivotal for ensuring the viability and success of ADCs in the therapeutic domain.

For instance, accelerating an innovative ADC design necessitating distinct purification processes demands a profound understanding of biologics processing. A seasoned CMO can offer filtration, chromatography, and formulation expertise supported by a comprehensive suite of analytical methods.

Supply Chain Complexities:

Importance of Strategic Supplier Selection

Starting ADC manufacturing at the designated commercial site early in the process can be advantageous. This can facilitate the earlier commencement of a multi-stage process characterization program, thus circumventing potential delays associated with tech transfers and comparability studies. An integrated CDMO overseeing multiple manufacturing stages can further curtail lead times. The ADC supply chain stands out as inherently intricate. The concurrent production of antibodies and small-molecule components often demands separate manufacturing facilities with unique skill sets. Coupled with the need for high safety precautions due to the molecules’ potency, ADC production requires a robust coordination framework across multiple supply chain nodes. Additionally, sourcing and lead time issues, such as raw material acquisition, antibody production, and analytical method development, further convolute the ADC supply chain, with several fractional timelines needing alignment for successful drug delivery.

Facility and Capacity Constraints in ADC Supply Chain:

Temperature stability and safe cytotoxin handling emerge as pivotal concerns in ADC storage. While the former poses challenges shared with other biologics, cytotoxins demand specialized handling protocols to mitigate contamination risks. Segregated storage, enhanced disposal mechanisms, and environmental considerations accentuate the supply chain’s complexity. Moreover, the limited number of manufacturers with ADC expertise raises questions about the industry’s capacity to meet surging demands. This capacity challenge is not solely production-centric but extends to R&D, safety protocols, and integrated analytics.

Strategies for Supply Chain Success

A crucial step in designing an efficient ADC supply chain is initiating a comprehensive risk assessment, including evaluating feasibility. For instance, if a company chooses to manufacture its product in one country, package it in another, and distribute it in yet another, it creates a layered and intricate supply chain. Each added layer brings challenges, especially when dealing with biologics and potentially hazardous substances like cytotoxins.

Early-stage ADC studies often remain within borders, reinforcing the importance of evaluating supply chain risks. An efficient risk assessment can predict and allow preemptive measures against possible challenges. The primary goal should be creating a scalable supply chain. While managing small quantities may seem straightforward initially, the real challenge arises when scaling up for production and distribution.

Experience has shown that a centralized control approach, combined with a standardized process, is preferred by many major pharmaceutical entities. They aim to simplify the process, ensuring minimized handoffs and adherence to Good Distribution Practice (GDP). A well-defined risk assessment strategy can pave the way for smooth operations and peace of mind.

Collaborating with multiple partners does come with its challenges. Yet, with the proper foresight and planning, potential pitfalls can be avoided. Understanding demand, whether for clinical studies or commercial sales, is vital. Precise data can guide realistic production planning, including batch size, facility choice, and staffing decisions. The right partner, aligned in communication, decision-making, and quality standards, is essential for a successful manufacturing relationship.

Ensuring Safety in ADC Production: A Delicate Balance of Innovation and Care

Occupational Exposure Limit (OEL) Insights

ADCs, while promising, aren’t without challenges. Systemic toxicities have been observed in some cases. Such adverse effects can be due to various reasons, including the presence of the antigen in healthy cells or the premature release of toxins from the linker. Payloads display different OELs, and this variation is attributed to a compound’s mechanism, its potency, and the volume of research data available. How the compound interacts with DNA, its inherent power, and the research public greatly influence its OEL set. The Occupational Exposure Limit or OEL associated with an ADC payload has hit records as low as 5-7 ng/m3. A default OEL of 5 ng/m3 is established for some payloads, especially those with limited data. The absolute lowest recorded was 1ng/m3. However, the question arises – how low can OELs go while still ensuring safety? The industry has set a threshold of 1 ng/m3. Even though containment is possible below this limit, ensuring the safety of the workers at these levels is challenging.

Antibody-drug conjugates (ADCs) are an innovative leap in the pharmaceutical landscape, especially in addressing formidable conditions like cancer. However, the journey to produce them is intricate, demanding precision at every step.

Determining Safe Handling of ADCs

- Understanding the Miniscule: The Sugar Crystal Analogy

To grasp the small quantities inherent in ADC production, envision sugar crystals. If five sugar crystals equate to about one milligram, one crystal represents roughly 200 micrograms. The recommended daily dosage of the vital component in ADCs is 200 nanograms. That’s a fractional 1/1,000th of one sugar crystal. Given these microscopic levels, stringent safety measures become paramount.

The risk of exposure in a manufacturing setting is multifaceted, influenced not only by the specific task at hand but also by the inherent properties of the substance involved. The duration and method of handling, be it during processing, cleaning, or troubleshooting, can markedly vary the potential for exposure. Equally pivotal is the quantity and dilution of the substance in question. The amount and concentration utilized can significantly affect exposure levels, making some tasks inherently riskier than others. Furthermore, the substance’s physical properties, such as its particle size and volatility, are crucial in determining the associated hazards.

A comprehensive evaluation of the entire manufacturing process is thus essential to pinpoint areas of maximum exposure risk. Certain stages, like weighing the core component of Antibody-Drug Conjugates (ADCs), can pose significant exposure challenges, given the exceedingly small quantities involved and their high potency.

- Industrial Hygiene: A Framework for Monitoring

In Antibody-Drug Conjugate (ADC) production, the paradigm of industrial hygiene serves as an indispensable blueprint for ensuring worker safety. Integral to this framework is the rigorous monitoring process, pivoted around three pivotal sample types. Firstly, personal measurements serve as direct barometers of an individual worker’s potential exposure to hazards. Secondly, static samples are indispensable in evaluating the effectiveness of implemented containment strategies. Finally, swab and wipe tests, though often overlooked, offer an encompassing perspective on the environmental hygiene and cleanliness of the production facility.

Interestingly, it is crucial to discern that heightened results in wipe tests are not unequivocal indicators of elevated airborne contaminant concentrations. However, these tests can shed light on operator practices and behaviors within production precincts, potentially highlighting areas of concern or laxity. An innovative approach in this domain involves surrogate monitoring, which employs benign substitutes in testing. This offers a hazard-free testing milieu, which is especially beneficial when integrating novel equipment. However, subsequent active pharmaceutical ingredient (API) testing is imperative for a granular and accurate exposure assessment.

The efficacy of these analytical methods is inherently contingent on a myriad of factors, not least of which are the occupational exposure limits (OELs). Adhering to international compliance standards, it is of paramount importance to ensure continuous monitoring, thus certifying that worker exposure remains within the safe confines of established limits.

- Establishing Exposure Limits for ADCs

Before initiating any ADC project, it’s essential to assess potential risks. One begins with a hazard assessment, determining Occupational Exposure Limits (OELs) and relevant occupational exposure bands. This assessment characterizes the ADC’s toxicological and pharmacological properties, which help set an OEL value for each component. OELs are benchmarks set after considering the possible adverse effects on humans exposed to a substance. These limits account for chronic exposure over an average 8-hour working day spanning a 40-year operational lifetime.

In some instances, when specific toxicity data might be missing, a default OEL approach is used, which leans on comparison processes involving structurally similar ADCs or ADCs with analogous payloads. In other scenarios where comprehensive data is available, the OEL is calculated based on documented safe doses and associated factors.

- Risk Evaluation and Containment Implementation

Once the hazard assessment phase is completed, expert teams utilize their occupational hygiene knowledge to undertake an exposure and risk assessment throughout the ADC’s lifecycle. These assessments help outline the best containment measures and conduct ongoing occupational hygiene surveillance. Typically, ADCs’ OELs and standard clinical doses fall within specific ranges, and understanding these can ensure a safe manufacturing environment.

In conclusion, ADC manufacturing is intricate, demanding specialized expertise in several areas, including toxicology and occupational hygiene. As the ADC market continues to grow, understanding and implementing these safety measures will remain paramount in ensuring that these promising therapies are produced in a manner that safeguards both the product and the people involved in its production.

- Monitoring Methods: A Diverse Landscape

The vast landscape of ADCs and their payloads requires diverse monitoring methods. Payloads, typically small molecules, are better suited for techniques like liquid chromatography-tandem mass spectrometry (LC-MS/MS). In contrast, ADCs, due to their larger molecular size, require the Elisa method for effective monitoring.

- Storage Protocols for ADCs

Storage remains crucial for ADCs. They are typically stored frozen in well-sealed cryo-vessels, ensuring stability. Further precautions include double packing in bags or bottles for added protection.

- Isolators and Payload Mixing

The payload weighing and mixing process is pivotal in ADC production, necessitating it to be done inside an isolator. With the right design, isolators can comfortably cater to upscaling needs, ensuring efficient production.

- ADCs vs. Immune-Mobilizing Monoclonal TCRs

Drawing comparisons between ADCs and immune-mobilizing monoclonal T-cell receptors (TCRs) highlights differences mainly in their mechanisms of action. While ADCs target specific cancer cells directly, immune-mobilizing monoclonal TCRs coax the immune system into attacking the malignant cells. These distinct modes of action and their different molecular weights mean their OEL considerations differ, emphasizing the need for nuanced approaches for each.

In the ever-evolving world of cancer treatment, understanding ADCs, their production, and their nuances is paramount. As we delve deeper into this arena, the potential for breakthroughs only amplifies.

The Future of ADCs

While ADCs have predominantly zeroed in on liquid cancers, a shift toward solid tumors is discernible. In an era where personalized medicine is gaining momentum, the allure of ADCs tailored for specific cancer subtypes is undeniable.

Conclusively, the journey of ADCs, albeit checkered with challenges, is one of promise and optimism. As research pioneers forward, the question isn’t if ADCs can redefine cancer treatment, but when. ADCs encapsulate the hope of a brighter, cancer-free future for patients and medical practitioners worldwide.

Conclusion:

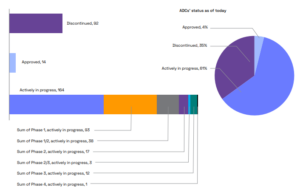

Antibody-drug conjugates (ADCs) are pivotal milestones in therapeutic innovations, seeking to fill the gaps in prevailing medical solutions. Out of 267 ADCs screened for oncology interventions, only 11 secured the FDA’s nod, whereas 92 met discontinuation. Investigating the hurdles these halted candidates encounter offers valuable lessons for tailoring future molecular endeavors. Encouragingly, recent strides in biological engineering hold promise, as showcased in preclinical trials, to amplify the therapeutic index. For the next wave of ADC successes, an integrated strategy is essential – one that underlines meticulous target selection, coupled with the fine-tuning of antibodies, linkers, and payloads in congruence with specific indications. Such a comprehensive approach, combined with honed manufacturing practices and strategic partnerships with expert CMOs, charts a lucid path towards ADC development and deployment, benefitting the pharmaceutical landscape and patients alike.

Antibody-drug conjugates (ADCs) are pivotal milestones in therapeutic innovations, seeking to fill the gaps in prevailing medical solutions. Out of 267 ADCs screened for oncology interventions, only 11 secured the FDA’s nod, whereas 92 met discontinuation. Investigating the hurdles these halted candidates encounter offers valuable lessons for tailoring future molecular endeavors. Encouragingly, recent strides in biological engineering hold promise, as showcased in preclinical trials, to amplify the therapeutic index. For the next wave of ADC successes, an integrated strategy is essential – one that underlines meticulous target selection, coupled with the fine-tuning of antibodies, linkers, and payloads in congruence with specific indications. Such a comprehensive approach, combined with honed manufacturing practices and strategic partnerships with expert CMOs, charts a lucid path towards ADC development and deployment, benefitting the pharmaceutical landscape and patients alike.

Opportunities and the Way Forward:

Despite inherent hurdles, the overarching sentiment in the industry is one of hope and anticipation. Signs of this upward momentum include escalating investments, emerging production facilities, and state-of-the-art manufacturing methodologies. For the ADC sector to truly flourish and realize its vast therapeutic potential, a synergistic melding of scientific breakthroughs with streamlined supply chain mechanisms is of the essence.

References:

This article was written by Dr Kishore Hotha and is extracted content from the following journal:

Hotha, K. (2023) Antibody-Drug Conjugates (ADCs): Navigating Four Pillars of Safety, Development, Supply Chain and Manufacturing Excellence. Advances in Chemical Engineering and Science, 13, 351-362. doi: 10.4236/aces.2023.134024.

ADCs are a harmonious blend of immunotherapy and chemotherapy, presenting formidable weapons against a spectrum of tumor types. Characterized by their ability to target over 50 distinct recognized antigens, ADCs predominantly focus on ERBB2, CD33, CD19, CD22, and MSLN (mesothelin). The idea is captivating yet intricate: direct a cytotoxic drug to its tumor target using an antibody linked through a carefully designed linker.

ADCs are a harmonious blend of immunotherapy and chemotherapy, presenting formidable weapons against a spectrum of tumor types. Characterized by their ability to target over 50 distinct recognized antigens, ADCs predominantly focus on ERBB2, CD33, CD19, CD22, and MSLN (mesothelin). The idea is captivating yet intricate: direct a cytotoxic drug to its tumor target using an antibody linked through a carefully designed linker. A partnership with seasoned CDMOs can streamline ADC manufacturing processes. With their profound understanding of scientific, technical, and regulatory aspects, these organizations can offer indispensable support throughout the ADC manufacturing lifecycle. The urgency to bring therapeutics to patients and achieve commercial success emphasizes minimizing time-to-market. A systematic approach involving process/analytical development, appropriate site selection for manufacturing, and performance qualification at the manufacturing scale can curtail the chances of unwanted late-stage alterations.

A partnership with seasoned CDMOs can streamline ADC manufacturing processes. With their profound understanding of scientific, technical, and regulatory aspects, these organizations can offer indispensable support throughout the ADC manufacturing lifecycle. The urgency to bring therapeutics to patients and achieve commercial success emphasizes minimizing time-to-market. A systematic approach involving process/analytical development, appropriate site selection for manufacturing, and performance qualification at the manufacturing scale can curtail the chances of unwanted late-stage alterations. Antibody-drug conjugates (ADCs) are pivotal milestones in therapeutic innovations, seeking to fill the gaps in prevailing medical solutions. Out of 267 ADCs screened for oncology interventions, only 11 secured the FDA’s nod, whereas 92 met discontinuation. Investigating the hurdles these halted candidates encounter offers valuable lessons for tailoring future molecular endeavors. Encouragingly, recent strides in biological engineering hold promise, as showcased in preclinical trials, to amplify the therapeutic index. For the next wave of ADC successes, an integrated strategy is essential – one that underlines meticulous target selection, coupled with the fine-tuning of antibodies, linkers, and payloads in congruence with specific indications. Such a comprehensive approach, combined with honed manufacturing practices and strategic partnerships with expert CMOs, charts a lucid path towards ADC development and deployment, benefitting the pharmaceutical landscape and patients alike.

Antibody-drug conjugates (ADCs) are pivotal milestones in therapeutic innovations, seeking to fill the gaps in prevailing medical solutions. Out of 267 ADCs screened for oncology interventions, only 11 secured the FDA’s nod, whereas 92 met discontinuation. Investigating the hurdles these halted candidates encounter offers valuable lessons for tailoring future molecular endeavors. Encouragingly, recent strides in biological engineering hold promise, as showcased in preclinical trials, to amplify the therapeutic index. For the next wave of ADC successes, an integrated strategy is essential – one that underlines meticulous target selection, coupled with the fine-tuning of antibodies, linkers, and payloads in congruence with specific indications. Such a comprehensive approach, combined with honed manufacturing practices and strategic partnerships with expert CMOs, charts a lucid path towards ADC development and deployment, benefitting the pharmaceutical landscape and patients alike.