Veranova specializes in the manufacture and development of specialist and complex Active Pharmaceutical Ingredients (API). The workflow from screening to clinical supply and finally to commercial manufacturing involves technology transfer between sites/groups and scale-up from lab scale (g) to kilo lab and subsequently to the plant scale (100s-1000s kg), depending on the API. This is quite a challenging problem with new modalities having significantly different complexity and properties than in the past. Traditionally, experiential knowledge of plant personnel, engineers, and chemists has been utilized for tech transfer and scale-up. However, it has been estimated that more than 60% of the new drug shortage is related to quality and manufacturing issues1. Mathematical modeling tools such as Computational Fluid Dynamics (CFD – OpenFoam®), MixIT®, Dynochem®, Visimix®, and gFormulate® can significantly de-risk scale-up and tech transfer to achieve the ‘right first-time’ product. Data science, chemometrics, and machine learning (ML) can significantly improve the ability to process transfer. Cloud computing affords significant advantages in scaling up CFD, ML, and chemometrics workflow to bigger and faster virtual machines with larger CPUs and GPUs.

Cloud computing: revolutionizing process development in the pharmaceutical industry

High-performance computing

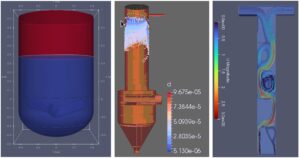

Veranova utilizes high-performance computing (HPC) to reduce the time to market for products. CFD is utilized mainly to understand and resolve issues with mixing heterogeneous reactions, crystallization, and spray drying. Open-source CFD software, is used for equipment evaluation and selection, design improvement, and tech transfer.

Figure 1: Typical applications of high-performance computing: a) Mixing scale-up/scale-down, b) Spray drying, c) Flow chemistry – T mixer

Cloud computing

Until recently, high-performance computing has been run on on-prem (on the premises) infrastructure. However, on-prem infrastructure is constrained by high upfront investment, limits to architecture upgrades, as well as potential for idle capacity during periods of lower demand. Thus, there are significant benefits to cloud computing, including instant access to high CPU and GPU nodes and faster computational time on demand without a large upfront investment. However, the journey to transfer from on-prem infrastructure to the cloud is quite time intensive with heavy involvement of outside consultants to design HPC architecture. These customized solutions could also be sub-optimal depending on the skills and experience of the consultant and the user experience.

Cloud computing architecture solution providers

We evaluated different primary cloud architecture providers and secondary solution providers. After completing the proof-of-concept evaluation, one primary solution provider was selected for the HPC production architecture for Veranova. The selected cloud partner has a significant advantage in comparison to other cloud providers in terms of low latency for large simulations across multiple virtual machines and full control of the software installed compared to secondary providers. Secondary solution providers reduce the load for architecture deployment on the cloud. However, these providers are much more expensive than the primary cloud providers and custom software would be difficult and time-consuming to deploy on an external architecture. Cloud computing infrastructure is up to 11 times faster compared to the 8-year-old on-prem solution it replaces.

Figure 2: CFD is significantly faster on the cloud (11x) compared to on-prem

Production architecture solution

We have deployed an open-source on-demand platform2 on our cloud partner infrastructure. This open-source platform was generated in collaboration between multiple academic and industry partners. The platform has been customized for the cloud provider keeping enterprise requirements of security and network connectivity in mind. It is easier to customize the architecture for production deployment by simply customizing the configuration files. The deployed platform generates a user-friendly web interface. A user can quickly launch a Linux desktop, code server (like Visual Studio and Linux terminal), Paraview for visualization, and Jupyter notebooks for Python applications. Grafana dashboards are automatically deployed for cluster management. Cloud computing allows us to run multiple simulations at the same time significantly reducing the solution time. Multiple simulations utilizing 10000s of CPU can be run in parallel to significantly reduce the waiting time for results. Simulations that would take approximately a month in-house and HPC could be completed in a few days in the cloud environment. This architecture can also be utilized for ML, chemometrics, data science, and visualization for chemical development projects and directly deployed for end users to improve our workflow.

A typical CFD workflow involves CAD, meshing, simulations run, and subsequent analysis of the results. A typical workflow would require high CPU core machines for CFD simulations and GPU nodes for visualization in Paraview. It is easier to deploy multiple machines quickly in the new platform. The whole workflow can be accessed using a web interface. We have deployed a hub and spoke architecture for easy access to HPC architecture from the on-prem network while ensuring network security. This HPC architecture has been quickly updated to the new latest architecture just by redeploying with the new configuration as a newer version of the on-demand software and newer hardware is released.

Outlook

Cloud computing offers numerous benefits to the pharmaceutical industry, including improved collaboration, scalability, cost savings, and enhanced data security. By leveraging cloud-based platforms and services, pharmaceutical companies can streamline their manufacturing processes, optimize supply chain management, and accelerate drug development. Cloud-based solutions enable real-time data sharing and collaboration among different teams, making it easier to track and manage manufacturing operations efficiently. To better serve our customers in getting the API to market quicker and to facilitate the ‘right first-time’ process scale-up, it is important to understand, design, and characterize our equipment. Spray drying and mixing in heterogeneous reactions such as liquid-gas-solid, crystallization can benefit significantly from our ability to simulate the process and de-risk scale-up and tech transfer. Cloud computing allows access to an enormous number of virtual machines with GPU and CPUs which wouldn’t be feasible without a very significant upfront investment. Cloud computing is multiple times faster than our in-house high-performance computing architecture. Overall, cloud computing holds great potential for transforming pharmaceutical manufacturing by enabling greater efficiency, collaboration, scalability, cost savings, and data security. It is expected that more pharmaceutical companies will adopt cloud-based solutions to drive innovation and stay competitive in the evolving healthcare landscape.

References:

- Shukar, S. et al. Drug Shortage: Causes, Impact, and Mitigation Strategies. Front. Pharmacol. 12, 693426 (2021).

- Read Our Story. https://openondemand.org/read-our-story (2023).

About the author

Dr. Ankur Kapil, Senior Process Engineer, Veranova

Dr. Ankur Kapil (Ph.D., CEng, MIChemE) is a Chartered Chemical Engineer with more than 15 years of experience in the continuous improvement of manufacturing processes in the pharma, chemicals & catalyst industries. Dr. Kapil has extensive expertise in the application of computational modeling and data science tools to spray drying, mixing, scale-up, multiphase reaction (hydrogenation), milling (wet & dry), batch to continuous, extrusion, & crystallization. He has 6 first-author publications in international journals and 13 presentations at international conferences. Dr. Kapil received his PhD from the University of Manchester, UK in the field of Chemical Engineering.