Techniques to enhance solubility

To successfully address solubility issues, it is crucial to understand the solid form landscape of a drug as early as possible. In recent years, the pharmaceutical industry has adapted to increasing complexity of novel APIs and new chemical entities, and a variety of techniques have been developed to characterize, evaluate and optimize the solubility of these compounds. These are typically split into two main groups:

Physical methods

These methods aim to improve solubility by modifying the particle attributes of an API or drug product. Examples include:

- Reduction of particle size: traditional methods include micronization or jet milling, wet milling incorporated into a controlled crystallization; more recently nano-milling, high-pressure homogenization and other methods to achieve sub-micron particles

- Stabilization of amorphous APIs – most commonly within a polymer matrix and scaled via spray drying or hot melt extrusion

Physicochemical modifications

These techniques aim to improve solubility through crystal engineering and other modifications. Examples include:

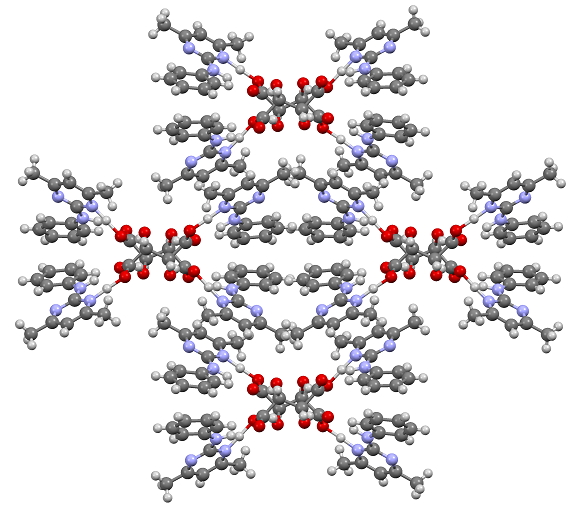

- Formation of salts or cocrystals

- Solubilization with surfactants

- Formation of complexes or molecular associations, e.g., via cyclodextrins

- Use of prodrugs, e.g., phosphate esters

- The introduction of hydrophilic groups into molecules

In recent years, a range of alternative techniques have been developed to increase solubility. These include hydrotropy, selective adsorption or use of insoluble transporters, use of cosolvents, use of polymeric micelles and nanoparticle formulations.

Crucially, however, there is no single approach to addressing solubility concerns in drug development, and each molecule requires a unique strategy based upon a full understanding of its properties. A wide range of factors must be considered, including absorption site, dosage concentration, drug stability, formulation, administration route, and economic influences. The optimal method for each molecule will therefore require a range of formulation procedures and technologies. Veranova can approach these with confidence, leveraging our integrated solid form and particle engineering services.

Managing complexity with confidence

At Veranova, we understand how solid form and particle engineering solutions can be harnessed to overcome solubility issues in drug development. We’ve been providing customers with leading solid form and particle engineering services for the past 20 years through our Pharmorphix® offering. Our services include physchem data packages, solid form screening and characterization, and particle engineering solutions.

Employing a holistic approach, we follow a candidate molecule fully through the development process, gathering data at every stage and accelerating its journey to market. By keeping the end product in mind throughout, Veranova works closely with its customers and partners to understand their target product profile (TPP) and ultimate end goal for a novel drug product.

This way, we help our partners to achieve their objectives from the start, including the route of administration, drug target, dosage form, and much more. Leveraging these factors allows Veranova to tailor its solutions to our customer’s needs and provide the expertise, technology, and thorough approach required to advance their projects through to market.

References:

1. S. Kalepu and V. Nekkanti, Acta Pharm. Sin. B., 5 (5) 442–453 (2015)

2. P. Parois, R. I. Cooper and A.L. Thompson, Chem Cent J., 9 (30) doi:10.1186/s13065-015-0105-4 (2015)