Understanding the demand for HPAPIs

HPAPIs, defined as compounds that elicit therapeutic effects at very low doses, are commonly categorized according to occupational exposure limits (OELs). Here, OELs represent an upper limit on the acceptable concentration of an API in workplace air. Typically, compounds with OELs < 10 μg/m3 are classed as highly potent.2

Despite the risks of working associated with highly potent molecules, HPAPIs have emerged as an exciting new class of pharmaceuticals due to their potential to provide several patient and therapeutic benefits.

Since low quantities of HPAPIs display high levels of pharmacological activity, toxicity and side effects can be reduced in patients.2 Moreover, highly potent compounds can remain in vivo for longer, which reduces the dosing frequency and minimizes the amount of medication the patient comes into contact with.2 And utilizing targeted treatments can further improve the overall efficacy by carrying the drug directly to the treatment site.

The increasing focus on HPAPIs is closely associated with and driven by the growing demand for more effective oncology treatments. In 2019, the oncology therapeutics sector accounted for 20% of global sales for branded pharmaceutical products.2 Yet, rising cancer rates continue to place increasing burdens on global healthcare systems. HPAPIs are a key tool to help the wider life science industry tackle these needs and improve patient outcomes with innovative, targeted, and potent therapies.

Due to their wide-ranging applications, highly potent molecules can be used as standalone therapies, as part of ADCs, or in combination therapies, such as immuno-oncology agents.2

Nick Shackley, Senior Vice President at Veranova, discussed the application of highly potent anti-cancer molecules for ADCs therapies in this Chemicals Knowledge Hub article: “ADCs aim to combine the potency of cytotoxic agents with the target selectivity of antibodies. This is done by chemically linking a cytotoxic payload to an antibody, creating a synthetic molecule that will deliver targeted anti-tumor therapy that is both safe and efficacious.”

The versatile nature of HPAPIs as a modality also allows them to be applied to treat a range of illnesses, including hormonal imbalances and respiratory disorders. With so many potential applications, it is crucial that HPAPI manufacturing is supervised by specialists with a diverse range of expertise.

Understanding the challenges associated with HPAPI development

HPAPI manufacture and development requires very complex and sophisticated technologies. The specialized infrastructure required to develop and manufacture HPAPIs must be continually assessed, maintained, and upgraded to respond to market demand for new HPAPIs.

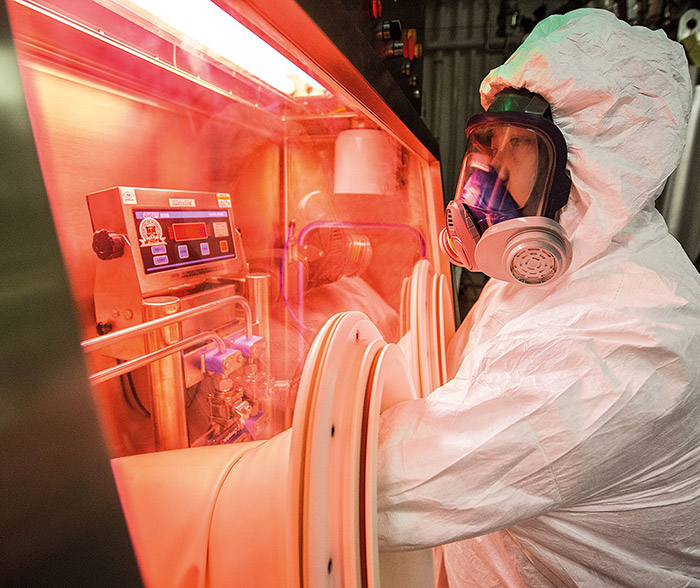

Worker safety must be ensured throughout HPAPI development. Since the risks associated with each HPAPI are different, management and containment strategies must be precisely designed and implemented, minimizing exposure to hazardous compounds through the careful transfer of compounds and correct use of PPE. These strategies must be enforced through rigorous training programs for employees working with HPAPIs.

When faced with these demands, companies are increasingly turning to CDMOs. Partnering with the right CDMO for a company’s needs ensures access to the facilities and analytical expertise needed to safely contain and develop HPAPIs.

Managing complexity with confidence

At Veranova, we understand the challenges associated with HPAPI formulation and manufacture. With increasing numbers of new HPAPIs under development, we can combine our extensive technical expertise with specialized equipment to produce and handle them safely.

Flexibility is crucial in ensuring that the equipment and safety procedures are exactly suited to the development process of a HPAPI. We are focused on understanding our customers’ problems to provide the best possible development and manufacturing solutions. Through our Custom Pharma Solutions offering, we follow a candidate molecule fully through its development process, from pre-clinical to commercialization, collaborating with our partners to ensure that their ultimate end goal for a novel drug product is fulfilled.

Get in contact with our experts to discover new ways to advance your highly potent drug development with Veranova.

References

- HPAPI Panel Discussion 2022, Chemistry Today, viewed January 2023, <https://www.teknoscienze.com/tks_article/panel-discussion-on-hpapis/>

- Mahdi, M 2020, Getting a Handle on High Potency: Panel Discussion, The Medicine Maker, viewed January 2023, <https://themedicinemaker.com/discovery-development/getting-a-handle-on-high-potency>